Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mould, and trimmed to create a usable product.

To stretch the sheet a mould is needed, the mould can be made of wood, epoxy, aluminiumother suitable materials. The film is heated in an oven to a high-enough temperature that permits it to be stretched into or onto the mould.

Once we have the product, it has to be cooled to the finished shape, thistoughens the material and allows it to be taken out of the mould.

The heating time and the temperature depends on the density or toughness of the sheet material.

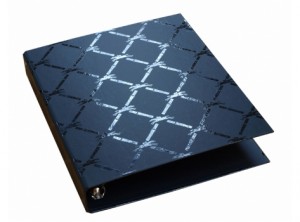

ADVANTAGES OF FOLDERS THERMOFORMING IN SAMPLE

The main advantage of Thermoforming is its low cost in comparison with other inject moulding systems, that is why it is feasible to manufacture small quantity of units. It is possible to tailor bespoke moulds for sample presenters without the necessity of doing large runs.

Another advantage is the wide range of materials that can be applied by the thermoforming system: PAI,PP,PSI, PET, ABS, PEAD, PVC., foam, polycarbonate and acrylic…

This special feature makes this system the most appropriate system to create every kind of mould and package, from sample presenters folders for every kind of sample out there to tailor made POS displays.

Once we have the thermoformed apertures, in the right sample presenter, the next step is to fill in the apertures in the tray with the samples to fitperfectly.The presentation then being ready for your customers or distributors.

Because of the flexibility and toughness of this system, the samples are able to be removed and replaced in into the tray again and again easily without deforming the tray and increasing the longevity of the sample presenter.

If the sample presenter requires it, we can also add thump trays for an easier extraction of the sample (marble, glass, tiles…)

As manufacturers, we do know the advantages and versatility of the thermoformed pieces, that is why we use it in our sample presenters.

Some of the most common applications are the sample presenters with an external paper over board and thermoformed trays inside mainly made of high quality PVC that works perfect for wood, mortars and other construction materials.

Related Posts:

Merchandising material for the tourism sector

The importance of corporate visual identity and merchandising